Building a sustainable legacy together

Driven by a commitment to achieve net zero CO₂ emissions by 2050, Daikin provides safe, healthy and comfortable indoor climates throughout the building life cycle using cutting-edge technology.

Daikin’s VRV 5 heat recovery represents a major milestone on the path of decarbonization of commercial buildings.

Unparalleled flexibility out of the box

Shirudo Thechnology

With Shîrudo technology, your VRV 5 system takes care of small room applications in your building without the need for any additional considerations, field supplied equipment or additional investments. Thanks to the factory-integrated measures, Daikin undertakes full responsibility about compliance to product standards while offering maximum flexibility, if the design is validated in Xpress and some simple installation requirements are respected.

Widest range of dedicated R-32 indoor units

Specially designed R-32 VRV indoor units offers maximum flexibility for all room configurations. A choice of capacities ranging from 1.1 kw to 31.5 kw easily covers all possible room sizes.

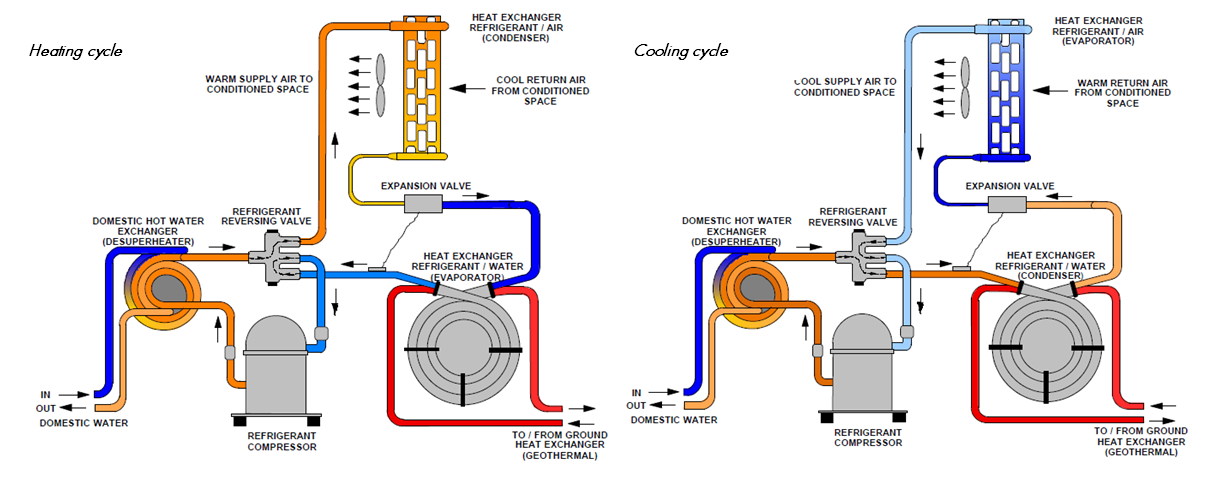

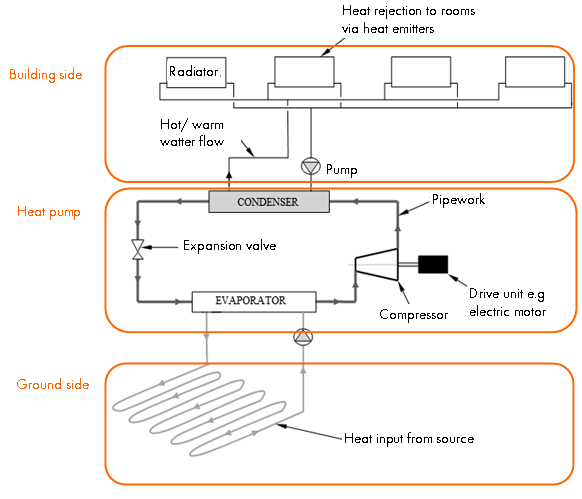

How does heat recovery work?

Daikin’s innovative heat recovery systems allows simultaneous cooling and heating. This is allows individual comfort control while enabling virtually free heating by transferring heat from areas requiring cooling to areas in need of heating. Our innovative heat recovery systems allows simultaneous cooling and heating. This is allows individual comfort control while enabling virtually free heating by transferring heat from areas requiring cooling to areas in need of heating.

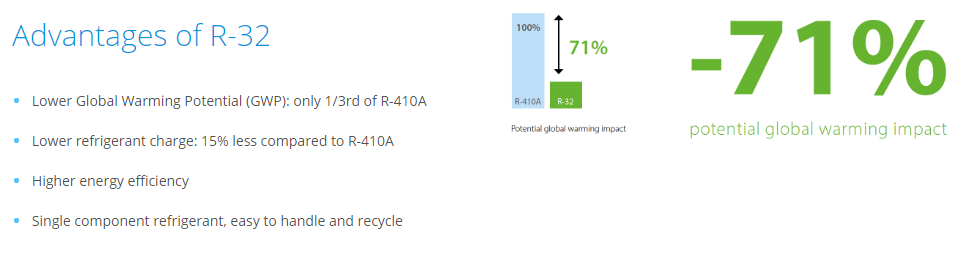

Bluevolution

Specially designed R-32 VRV indoor units offers maximum flexibility for all room configurations. A choice of capacities ranging from 1.1 kw to 31.5 kw easily covers all possible room sizes.

Via Daikin

Images: Shutterstock

Contact Us If You Have Any Questions

We are a proficient company offering a wide selection of services for all size projects in the areas of Solar Energy, Photovoltaic Systems, Geothermal Energy, Net Metering, Swimming Pools, Air Conditioning, Central Heating, all kind of Mechanical Installations. Please contact us if you have any questions!